Working in a warehouse involves numerous hazards. Loading and unloading goods, operating forklifts, or working at height all carry the risk of accidents that may result in serious injuries or financial losses. In this article, you will learn what to watch out for and what actions to take to minimize the likelihood of such incidents.

Warehouse work – hazards and risks

Daily work in warehouse halls requires a high level of attention and awareness of existing risks. The most common warehouse hazards include:

Falls from height – in warehouses where goods are stored on high shelves, there is a risk of falls during handling operations or maintenance work.

Collisions with forklifts – working in a warehouse where forklifts are constantly in motion can lead to dangerous situations such as being struck by a vehicle, property damage, or even fatal accidents.

Improper lifting and carrying of heavy items – incorrect handling techniques can result in spinal injuries and other health issues.

Inadequate infrastructure – poorly designed or insufficiently protected warehouse infrastructure, such as high-bay racking or loading ramps, can lead to numerous accidents.

Awareness of these hazards is the first step toward reducing accidents in warehouse work. Occupational health and safety rules as well as appropriate infrastructure also play a crucial role in minimizing risk.

Health and safety in warehouse work – what does it cover?

Health and safety regulations are designed to protect the health and lives of employees. When it comes to warehouse safety, these procedures are particularly important, as even minor negligence can lead to serious accidents.

Basic health and safety elements in warehouse work include:

- Safety training – every warehouse employee should regularly participate in OHS training to stay aware of current hazards and safe work practices.

- Appropriate protective clothing – helmets, gloves, safety footwear, and high-visibility vests are essential elements of every warehouse worker’s equipment.

- Occupational risk assessment – before starting any warehouse work, potential hazards should be analyzed and preventive measures established. You can learn more about this in the article occupational risk assessment.

- Regular infrastructure inspections – equipment used in the warehouse, such as forklifts, racking systems, and lifts, should be regularly checked for technical condition and safety.

Failure to comply with these procedures is a direct path to escalating hazards in the warehouse.

Warehouse hazards – how to eliminate them?

To effectively eliminate hazards in warehouse work, a comprehensive approach is required—one that includes both employee education and the provision of appropriate tools and infrastructure.

- Implementation of monitoring and control systems – modern warehouses should be equipped with systems that monitor forklift operation and goods flow, allowing for quick detection of potential hazards.

- Compliance with OHS standards – continuous reminders about safety rules, regular training, and warehouse audits are essential elements of effective risk management.

- Modern risk assessment systems – risk assessment should be dynamic and regularly updated. It is worth using proven techniques such as risk score methods, which allow for quick and accurate evaluation of potential hazards.

Risk management requires a systematic approach. Regular audits, implementation of new technologies, and maintaining proper infrastructure are key elements that can significantly improve warehouse safety.

Infrastructure and hazards in warehouse work

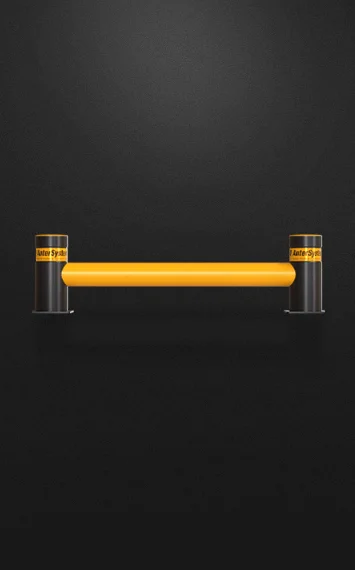

Proper infrastructure is a key factor that can significantly reduce accidents in warehouse operations. Solid, well-designed racking systems, trailer supports, protective barriers, and industrial gates ensure a higher level of safety in the warehouse.

Anter System, as a leader in providing solutions for warehouses and logistics centers, offers a wide range of products that help improve workplace safety.

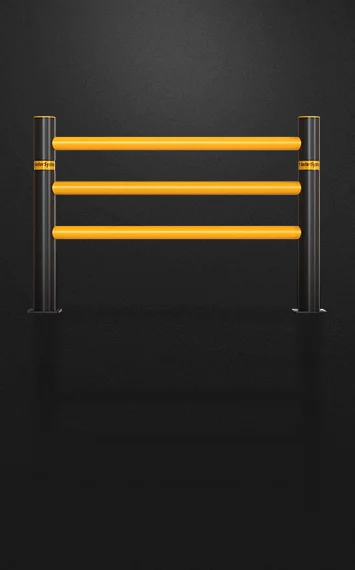

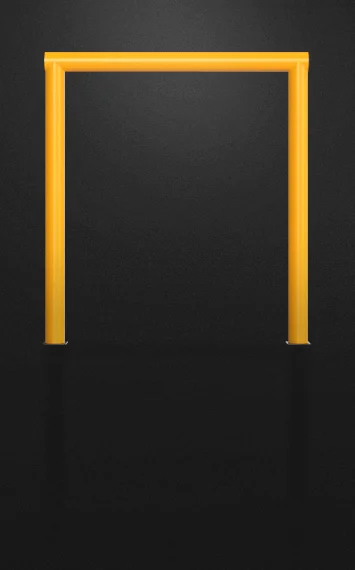

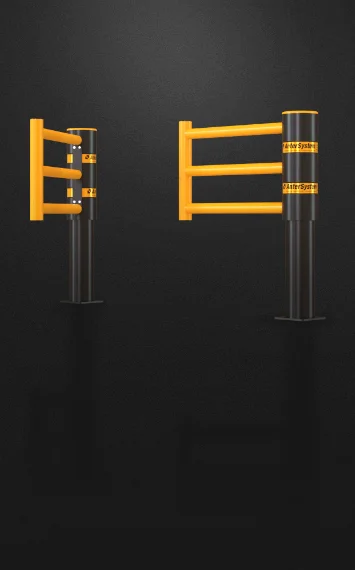

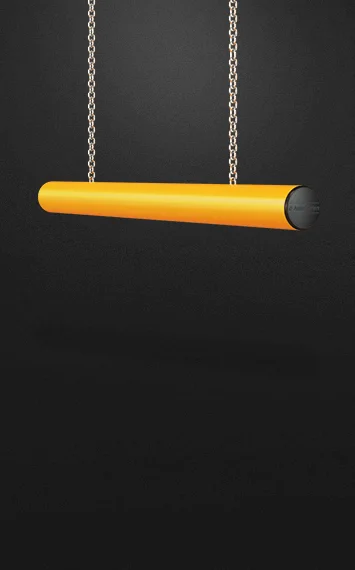

Our assortment includes protective rails and bollards, impact plates, high-bay barriers, rack protectors, and much more.

Anter System products are designed to meet the highest safety standards while also supporting efficient daily warehouse operations. We encourage you to explore our full range of solutions and read other articles that will help you further reduce hazards in warehouse work. You can learn more about how to prevent workplace accidents.